|

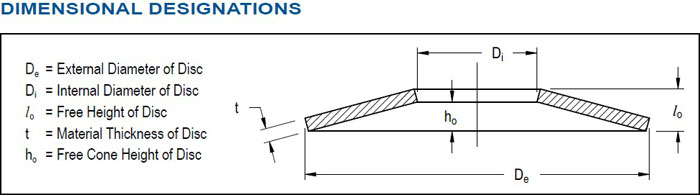

Disc springs are conically-shaped, washer-type components designed to be axially loaded. We makes disc springs as per DIN 2093, the deflection for a given load is predictable and the minimum life cycle can be determined. Disc springs can be statically loaded either continuously or intermittently, or dynamically subjected to continuous load cycling. They can be used singly or in multiples stacked parallel, in series or in a combination thereof.

The advantages of disc springs compared to other types of springs include the following:

* A wide range of load/defl ection characteristics

* High load capacity with small deflection

* Space savings – high load to size ratio

* No set under design loads

* Longer fatigue life

* Inherent dampening especially with parallel stacking

* Flexibility in stack arrangement to meet your application requirements

Disc spring range:

Parts according to Din 2093 disc springs are listed into 3 groups.

Group 1 Material thickness < 1.25mm

Group 2 Material thickness 1.25 - 6.0mm

Group 3 Material thickness > 6.0 - 14mm

We also produce non-standard disc spring as per your request.

● Disc spring complementarity sizes

● Non-standard sizes of disc spring

Technical and Design Guideline:

Material Dimensional Tolerance Surface Finish

Application Stacking Production Process

Applications with disc springs in use

o Control Safety Valve

o Automatic Quick Tool Changer (CNC Machines, etc.)

o Torque Converter

o Clutches Manual Transmission

o Nozzle of Spray Injection Moulding Unit

o Brake System

o Brake Slack Adjuster

o Stamping Machine

o Damper

o Over Load Protection

Disc spring specification (Unit:inch PDF download)

DIN2093(GB/T1972-2005) |

Serial A D/t≈18;h0/t≈0.4;E=206000N/mm2 ;μ=0.30 |

Item no. |

D/mm |

d/mm |

t(t′)/mm |

h0/mm |

H0/mm |

f≈0.75h0 |

Q/KG/

1000pcs |

f/mm |

(H0-f)/mm |

F/N |

σ om/

N/mm2 |

σⅡ、σⅢ

/N/mm2 |

A1 |

8 |

4.2 |

0.4 |

0.2 |

0.6 |

0.15 |

0.45 |

210 |

-1200 |

1220* |

0.114 |

A2 |

10 |

5.2 |

0.5 |

0.25 |

0.75 |

0.19 |

0.56 |

329 |

-1210 |

1240* |

0.225 |

A3 |

12.5 |

6.2 |

0.7 |

0.3 |

1 |

0.23 |

0.77 |

673 |

-1280 |

1420* |

0.508 |

A4 |

14 |

7.2 |

0.8 |

0.3 |

1.1 |

0.23 |

0.87 |

813 |

-1190 |

1340* |

0.711 |

A5 |

16 |

8.2 |

0.9 |

0.35 |

1.25 |

0.26 |

0.99 |

1000 |

-1160 |

1290* |

1.05 |

A6 |

18 |

9.2 |

1 |

0.4 |

1.4 |

0.3 |

1.1 |

1250 |

-1170 |

1300* |

1.48 |

A7 |

20 |

10.2 |

1.1 |

0.45 |

1.55 |

0.34 |

1.21 |

1530 |

-1180 |

1300* |

2.01 |

A8 |

22.5 |

11.2 |

1.25 |

0.5 |

1.75 |

0.38 |

1.37 |

1950 |

-1170 |

1320* |

2.94 |

A9 |

25 |

12.2 |

1.5 |

0.55 |

2.05 |

0.41 |

1.64 |

2910 |

-1210 |

1410* |

4.4 |

A10 |

28 |

14.2 |

1.5 |

0.65 |

2.15 |

0.49 |

1.66 |

2850 |

-1180 |

1280* |

5.39 |

A11 |

31.5 |

16.3 |

1.75 |

0.7 |

2.45 |

0.53 |

1.92 |

3900 |

-1190 |

1320* |

7.84 |

A12 |

35.5 |

18.3 |

2 |

0.8 |

2.8 |

0.6 |

2.2 |

5190 |

-1210 |

1330* |

11.4 |

A13 |

40 |

20.4 |

2.25 |

0.9 |

3.15 |

0.68 |

2.47 |

6540 |

-1210 |

1340* |

16.4 |

A14 |

45 |

22.4 |

2.5 |

1 |

3.5 |

0.75 |

2.75 |

7720 |

-1150 |

1300* |

23.5 |

A15 |

50 |

25.4 |

3 |

1.1 |

4.1 |

0.83 |

3.27 |

12000 |

-1250 |

1430* |

34.3 |

A16 |

56 |

28.5 |

3 |

1.3 |

4.3 |

0.98 |

3.32 |

11400 |

-1180 |

1280* |

43 |

A17 |

63 |

31 |

3.5 |

1.4 |

4.9 |

1.05 |

3.85 |

15000 |

-1140 |

1300* |

64.9 |

A18 |

71 |

36 |

4 |

1.6 |

5.6 |

1.2 |

4.4 |

20500 |

-1200 |

1330* |

91.8 |

A19 |

80 |

41 |

5 |

1.7 |

6.7 |

1.28 |

5.42 |

33700 |

-1260 |

1460* |

145 |

A20 |

90 |

46 |

5 |

2 |

7 |

1.5 |

5.5 |

31400 |

-1170 |

1300* |

184.5 |

A21 |

100 |

51 |

6 |

2.2 |

8.2 |

1.65 |

6.55 |

48000 |

-1250 |

1420* |

273.7 |

A22 |

112 |

57 |

6 |

2.5 |

8.5 |

1.88 |

6.62 |

43800 |

-1130 |

1240* |

343.8 |

A23 |

125 |

64 |

8(7.5) |

2.6 |

10.6 |

1.95 |

8.65 |

85900 |

-1280 |

1330* |

533 |

A24 |

140 |

72 |

8(7.5) |

3.2 |

11.2 |

2.4 |

8.8 |

85300 |

-1260 |

1280* |

666.6 |

A25 |

160 |

82 |

10(9.4) |

3.5 |

13.5 |

2.63 |

10.87 |

139000 |

-1320 |

1340* |

1094 |

A26 |

180 |

92 |

10(9.4) |

4 |

14 |

3 |

11 |

125000 |

-1180 |

1200* |

1387 |

A27 |

200 |

102 |

12(11.25) |

4.2 |

16.2 |

3.15 |

13.05 |

183000 |

-1210 |

1230* |

2100 |

A28 |

225 |

112 |

12(11.25) |

5 |

17 |

3.75 |

13.25 |

171000 |

-1120 |

1140 |

2640 |

A29 |

250 |

127 |

14(13.1) |

5.6 |

19.6 |

1.2 |

15.4 |

249000 |

-1200 |

1220 |

3750 |

Serial B D/t≈28;h0/t≈0.75;E=206000N/mm2 ; μ=0.30 |

Item no. |

D/mm |

d/mm |

t(t′)/mm |

h0/mm |

H0/mm |

f≈0.75h0 |

Q/kg/

1000pcs |

f/mm |

(H0-f)/mm |

F/N |

σ om/

N/mm2 |

σⅡ、σⅢ

/N/mm2 |

B1 |

8 |

4.2 |

0.3 |

0.25 |

0.55 |

0.19 |

0.36 |

119 |

-1140 |

1330 |

0.086 |

B2 |

10 |

5.2 |

0.4 |

0.3 |

0.7 |

0.23 |

0.47 |

213 |

-1170 |

1300 |

0.180 |

B3 |

12.5 |

6.2 |

0.5 |

0.35 |

0.85 |

0.26 |

0.59 |

291 |

-1000 |

1110 |

0.363 |

B4 |

14 |

7.2 |

0.5 |

0.4 |

0.9 |

0.3 |

0.6 |

279 |

-970 |

1100 |

0.444 |

B5 |

16 |

8.2 |

0.6 |

0.45 |

1.05 |

0.34 |

0.71 |

412 |

-1010 |

1120 |

0.698 |

B6 |

18 |

9.2 |

0.7 |

0.5 |

1.2 |

0.38 |

0.82 |

572 |

-1040 |

1130 |

1.03 |

B7 |

20 |

10.2 |

0.8 |

0.55 |

1.35 |

0.41 |

0.94 |

745 |

-1030 |

1110 |

1.46 |

B8 |

22.5 |

11.2 |

0.8 |

0.65 |

1.45 |

0.49 |

0.96 |

710 |

-962 |

1080 |

1.88 |

B9 |

25 |

12.2 |

0.9 |

0.7 |

1.6 |

0.53 |

1.07 |

868 |

-938 |

1030 |

2.64 |

B10 |

28 |

14.2 |

1 |

0.8 |

1.8 |

0.6 |

1.2 |

1110 |

-961 |

1090 |

3.59 |

B11 |

31.5 |

16.3 |

1.25 |

0.9 |

2.15 |

0.68 |

1.47 |

1920 |

-1090 |

1190 |

5.6 |

B12 |

35.5 |

18.3 |

1.25 |

1 |

2.25 |

0.75 |

1.5 |

1700 |

-944 |

1070 |

7.13 |

B13 |

40 |

20.4 |

1.5 |

1.15 |

2.65 |

0.86 |

1.79 |

2620 |

-1020 |

1130 |

10.95 |

B14 |

45 |

22.4 |

1.75 |

1.3 |

3.05 |

0.98 |

2.07 |

3660 |

-1050 |

1150 |

16.4 |

B15 |

50 |

25.4 |

2 |

1.4 |

3.4 |

1.05 |

2.35 |

4760 |

-1060 |

1140 |

22.9 |

B16 |

56 |

28.5 |

2 |

1.6 |

3.6 |

1.2 |

2.4 |

4440 |

-963 |

1090 |

28.7 |

B17 |

63 |

31 |

2.5 |

1.75 |

4.25 |

1.31 |

2.94 |

7180 |

-1020 |

1090 |

46.4 |

B18 |

71 |

36 |

2.5 |

2 |

4.5 |

1.5 |

3 |

6730 |

-934 |

1060 |

57.7 |

B19 |

80 |

41 |

3 |

2.3 |

5.3 |

1.73 |

3.57 |

10500 |

-1030 |

1140 |

87.3 |

B20 |

90 |

46 |

3.5 |

2.5 |

6 |

1.88 |

4.12 |

14200 |

-1030 |

1120 |

129.1 |

B21 |

100 |

51 |

3.5 |

2.8 |

6.3 |

2.1 |

4.2 |

13100 |

-926 |

1050 |

159.7 |

B22 |

112 |

57 |

4 |

3.2 |

7.2 |

2.4 |

4.8 |

17800 |

-963 |

1090 |

229.2 |

B23 |

125 |

64 |

5 |

3.5 |

8.5 |

2.63 |

5.87 |

30000 |

-1060 |

1150 |

355.4 |

B24 |

140 |

72 |

5 |

4 |

9 |

3 |

6 |

27900 |

-970 |

1100 |

444.4 |

B25 |

160 |

82 |

6 |

4.5 |

10.5 |

3.38 |

7.12 |

41100 |

-1000 |

1110 |

698.3 |

B26 |

180 |

92 |

6 |

5.1 |

11.1 |

3.83 |

7.27 |

37500 |

-895 |

1040 |

885.4 |

B27 |

200 |

102 |

8(7.5) |

5.6 |

13.6 |

4.2 |

9.4 |

76400 |

-1060 |

1250 |

1369 |

B28 |

225 |

112 |

8(7.5) |

6.5 |

14.5 |

4.88 |

9.62 |

70800 |

-951 |

1180 |

1761 |

B29 |

250 |

127 |

10(9.4) |

7 |

17 |

5.25 |

11.75 |

119000 |

-1050 |

1240 |

2687 |

Serial C D/t≈40;h0/t≈1.30;E=206000N/mm2;μ=0.30 |

Item no. |

D/mm |

d/mm |

t(t′)/mm |

h0/mm |

H0/mm |

f≈0.75h0 |

Q/kg/

1000pcs |

f/mm |

(H0-f)/mm |

F/N |

σ om/

N/mm2 |

σⅡ、σⅢ

/N/mm2 |

C1 |

8 |

4.20 |

0.20 |

0.25 |

0.45 |

0.19 |

0.26 |

39 |

-762 |

1040 |

0.057 |

C2 |

10 |

5.2 |

0.25 |

0.3 |

0.55 |

0.23 |

0.32 |

58 |

-734 |

980 |

0.112 |

C3 |

12.5 |

6.2 |

0.35 |

0.45 |

0.8 |

0.34 |

0.46 |

152 |

-944 |

1280 |

0.251 |

C4 |

14 |

7.2 |

0.35 |

0.45 |

0.8 |

0.34 |

0.46 |

123 |

-769 |

1060 |

0.311 |

C5 |

16 |

8.2 |

0.4 |

0.5 |

0.9 |

0.38 |

0.52 |

155 |

-751 |

1020 |

0.466 |

C6 |

18 |

9.2 |

0.45 |

0.6 |

1.05 |

0.45 |

0.6 |

214 |

-789 |

1110 |

0.661 |

C7 |

20 |

10.2 |

0.5 |

0.65 |

1.15 |

0.49 |

0.66 |

254 |

-772 |

1070 |

0.912 |

C8 |

22.5 |

11.2 |

0.6 |

0.8 |

1.4 |

0.6 |

0.8 |

425 |

-883 |

1230 |

1.41 |

C9 |

25 |

12.2 |

0.7 |

0.9 |

1.6 |

0.68 |

0.92 |

601 |

-936 |

1270 |

2.06 |

C10 |

28 |

14.2 |

0.8 |

1 |

1.8 |

0.75 |

1.05 |

801 |

-961 |

1300 |

2.87 |

C11 |

31.5 |

16.3 |

0.8 |

1.05 |

1.85 |

0.79 |

1.06 |

687 |

-810 |

1130 |

3.58 |

C12 |

35.5 |

18.3 |

0.9 |

1.15 |

2.05 |

0.86 |

1.19 |

831 |

-779 |

1080 |

5.14 |

C13 |

40 |

20.4 |

1 |

1.3 |

2.3 |

0.98 |

1.32 |

1020 |

-772 |

1070 |

7.3 |

C14 |

45 |

22.4 |

1.25 |

1.6 |

2.85 |

1.2 |

1.65 |

1890 |

-920 |

1250 |

11.7 |

C15 |

50 |

22.4 |

1.25 |

1.6 |

2.85 |

1.2 |

1.65 |

1550 |

-754 |

1040 |

14.3 |

C16 |

56 |

28.5 |

1.5 |

1.95 |

3.45 |

1.46 |

1.99 |

2620 |

-879 |

1220 |

21.5 |

C17 |

63 |

31 |

1.8 |

2.35 |

4.15 |

1.76 |

2.39 |

4240 |

-985 |

1350 |

33.4 |

C18 |

71 |

36 |

2 |

2.6 |

4.6 |

1.95 |

2.65 |

5140 |

-971 |

1340 |

46.2 |

C19 |

80 |

41 |

2.25 |

2.95 |

5.2 |

2.21 |

2.99 |

6610 |

-982 |

1370 |

65.5 |

C20 |

90 |

46 |

2.5 |

3.2 |

5.7 |

2.4 |

3.3 |

7680 |

-935 |

1290 |

92.2 |

C21 |

100 |

51 |

2.7 |

3.5 |

6.2 |

2.63 |

3.57 |

8610 |

-895 |

1240 |

123.2 |

C22 |

112 |

57 |

3 |

3.9 |

6.9 |

2.93 |

3.97 |

10500 |

-882 |

1220 |

171.9 |

C23 |

125 |

61 |

3.5 |

4.5 |

8 |

3.38 |

4.62 |

15100 |

-956 |

1320 |

248.9 |

C24 |

140 |

72 |

3.8 |

4.9 |

8.7 |

3.68 |

5.02 |

17200 |

-904 |

1250 |

337.7 |

C25 |

160 |

82 |

4.3 |

5.6 |

9.9 |

4.2 |

5.7 |

21800 |

-892 |

1240 |

500.4 |

C26 |

180 |

92 |

4.8 |

6.2 |

11 |

4.65 |

6.35 |

26400 |

-869 |

1200 |

708.4 |

C27 |

200 |

102 |

5.5 |

7 |

12.5 |

5.25 |

7.25 |

36100 |

-910 |

1250 |

100 |

C28 |

225 |

112 |

6.5(6.2) |

7.1 |

13.6 |

5.33 |

8.27 |

44600 |

-840 |

1140 |

1456 |

C29 |

250 |

127 |

7(6.7) |

7.8 |

14.8 |

5.85 |

8.95 |

50500 |

-814 |

1120 |

1915 |

|